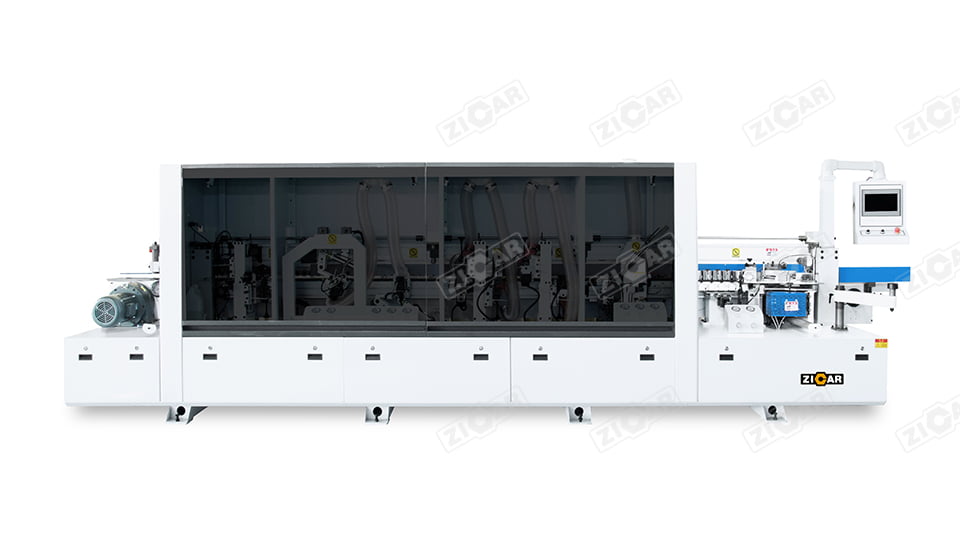

# Touch screen control panel

Convenient operation, quick response, and can display error alarm at the same time, convenient for maintenance

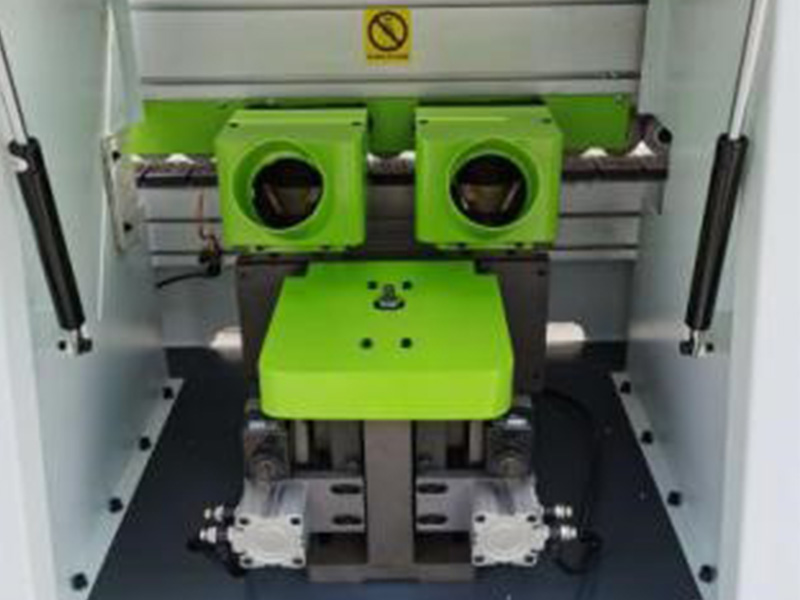

# Pre-milling

The diamond pre-milling cutter mills away the unnecessary burrs of the board,

and the pneumatically controlled pre-milling seat is more precise and easier to control.

# Gluing

The cylinder controls the opening and closing of the glue door (WSM cylinder and EASUN solenoid valve),

with stable glue volume and uniform thickness.

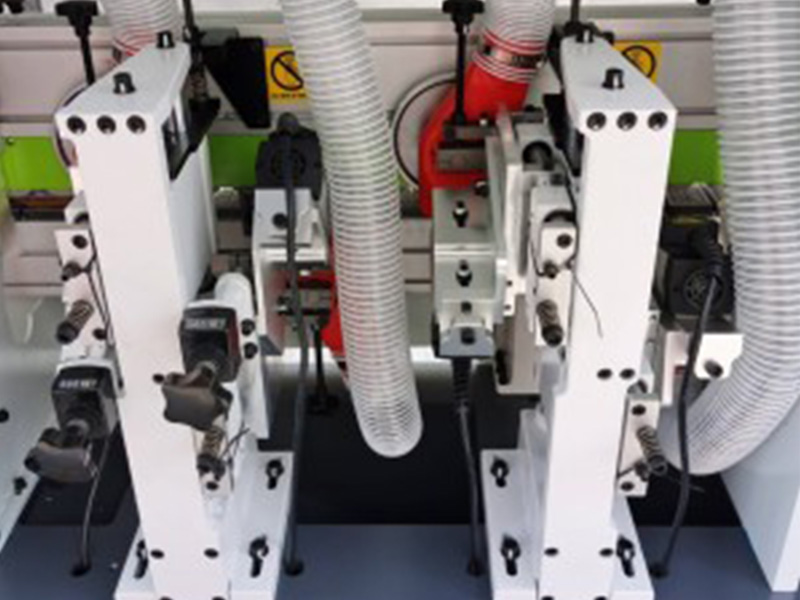

# End cutting

Cut off the excess edge banding at both ends of the working pieces (WSM cylinder with 2 pressure regulating valves

and 1 pressure relief valve), the air pressure is more stable, and the end is more stable.

# Rough trimming

Six-blade alloy flat knife trims off the excess edges

# Fine trimming

The six-blade R knife trims off the excess edge banding to form a round corner, and the trimming is more beautiful

# Corner trimming

The four corners after the edge banding are trimmed into small arcs to make them smoother and not piercing.

The self-designed tracking action and gas path design make the corner trimming action more stable.

# Scraping

The super hard alloy R knife scrapes the fine lines of the edge banding strip to make it smooth.

# Buffing

The cloth wheel quickly polishes the edge of the edge band, which is more smooth and beautiful.

# Centralized Lubrication System

Automatic timing oil injection maintenance, multi-channel oil pipes are connected to each key moving parts,

all-round lubrication, reducing machine wearing and extend machine life.

# Cleaning device (standard accessory)

Clean the residual glue of the board

# Narrow plate auxiliary wheel (Optional)

Auxiliary pin support wheels are installed at each functional focus point on the forward path of the boards,

which can support the narrow and small plates, and will not warp or drop the board. The narrowest width can be 4.5mm.

# Plate pressing device (optional)

The narrow and small plates will not shake or shift due to external force when passing through the pressing and aligning positions,

and the work is more stable

# Feeder (optional accessory)

The feeder for narrow and small plates is used as a standard for feeding plates with high safety and efficiency

# Pre-heat (Optional)

Preheat the board to make the edge banding better fit to the workpiece