edge banding machines designed for artisan craftsmen who want to improve and automate production, or for industry sectors manufacturing made-to-measure products.

share to:

edge banding machines designed for artisan craftsmen who want to improve and automate production, or for industry sectors manufacturing made-to-measure products.

|

Model |

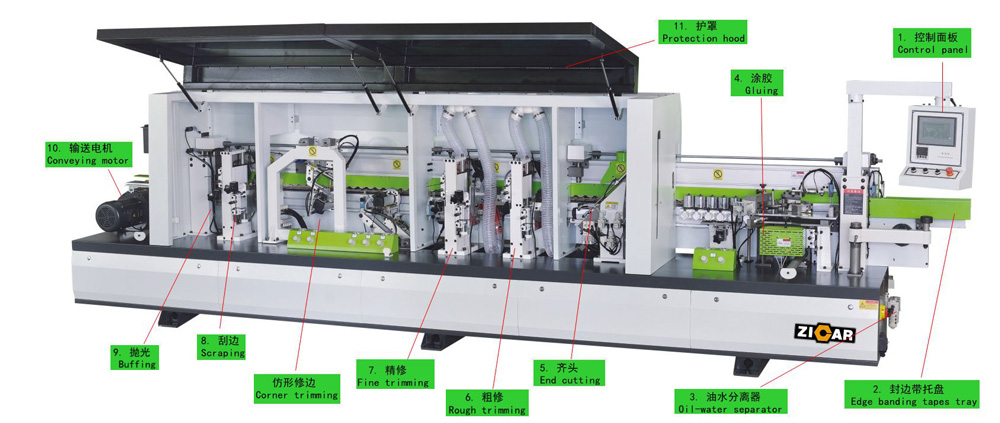

ZICAR Brand MF50D Corner Trimming Edge Banding Machine |

|

Panel width |

≥80mm |

|

Panel thickness |

10-60mm |

|

Edge thickness |

0.4-3mm |

|

Feeding Speed |

12-20m/min |

|

Working Pressure |

0.6Mpa |

|

Motor Power |

9.5kw |

|

Machine size |

5200*1000*1600mm |

|

Net weight |

1900kg |

1.Gluing

Dual glue pot, Quick Melt Glue System

2.End cutting

Dual Motor End Trim

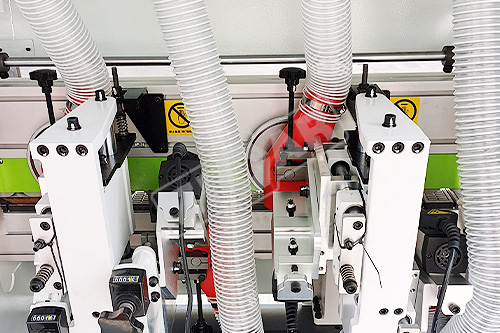

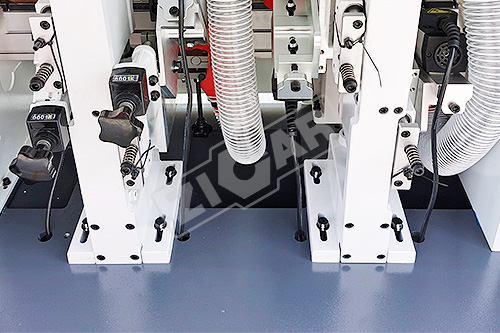

3.Rough and Fine Trimming

Top & Bottom Trim

Maximum precision Reliability and cutting precision thanks to the Edge-Trimming Unit, eliminating excess at each end of the panel.

4.Corner Trimming

Designed to remove microwaves on the machined radius surface of the edge after milling units.

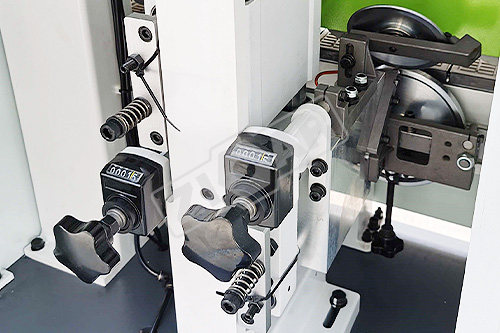

5.Scraping

The super hard alloy R knife scrapes the fine lines of the edge banding strip to make it smooth.

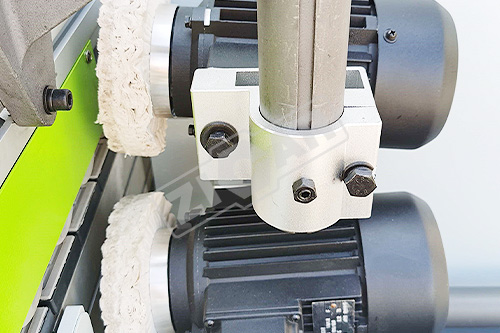

6.Buffing

POLISHING UNIT

Polishing is required for finishing the edgebanding. This operation provides:

The gloss of the treated surface, cleans from dirt.

Polishing unit - two motors, two polishing wheels

| Item | Description |

| Panel Length | Min.150mm |

| Panel Width | Min. 80mm |

| Panel Thickness | 10-60mm |

| Edge Thickness | 0.4-3mm |

| Feeding Speed | 15~23m/min |

| Working Pressure | 0.6Mpa |

| Net Weight | 1900kg |

| Total Power | 12Kw |

| Overall Size | 5840x970x1650mm |

| Packing Size | 5840x970x1650mm |

Please fill in the form with your details and we will get back to you as soon as possible.

Frequently Asked Question

What kind of machine you offer?

How to choose suitable machine?

How long is the machine leading time?

Oversea Service (Technical Assistance)

Could you ship machines to my country? If possible, could you make DTD?

How long is guarantee?

Where and how long can we get the replacement parts?

Payment Terms

Could you make the machine according my own requirements?